RBR Machine CNC Machining Services

Why Use RBR Machine for Custom CNC Machining Services?

Accurate & fast quotes available for custom metal and plastic machined custom parts with our CNC services. RBR Machine offers speedy turnaround times for all full production runs and prototypes. Rest assured, RBR Machine is certified to ISO 9001:2015, ISO 13485 and AS9100D standards and registered with ITAR.

We provide quality machine custom parts for a variety of industries, including oil and gas, aerospace, automotive, solar and wind energy, nuclear and agriculture.

With every client, our goal is the same: transparency and integrity, with a focus on exceeding your expectations for quality, delivery and value. Find out how RBR Machine can meet the needs of your company.

Click To See What We're Capable Of

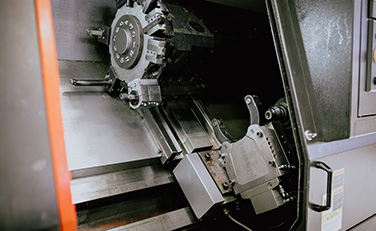

Leading 5-Axis CNC Machining Company

When it comes to manufacturing, machining and 5 axis CNC milling, precision matters. And so does the speed at which you can get the custom parts you need. The moment you begin working with us, we hit the ground running. Your project is our top priority. Quality, precision, and timing are on the forefront of our mind. Every piece that we create is reviewed in our shop prior to shipping out. The reason being to ensure that we deliver products that meet your exact specifications!

Get Your CNC Machining Quote Now

Custom CNC Machining Services: Machining, Turning, and Milling

Using RBR Machine means you are working with the nation’s top precision and 5 axis CNC machining specialists. Whether you need wire cut EDM, turnkey manufacturing, cmm inspection inspection, or CNC turning, our experienced machinists are ready and waiting. Click the link below for an ACCURATE and FAST quote!

If you don’t find what you are looking for on our site, just give us a call. We are always happy to provide more information over the phone.

Areas We ServeCNC Machining Services for Aerospace, Defense, and More

Precision Machine Shop

RBR Machine is an all-in-one manufacturing facility that focuses on creation of high-precision, tight tolerance parts using state of the art equipment and manufacturing processes. Our main priority as a precision machine shop is to provide our clients a consistent, reliable, and high-quality part(s) that meet their exact requirements. We use a variety of different machining techniques to meet the needs of our customers in a variety of different industries.

Turnkey Manufacturing

RBR Machine can truly do it all. Turnkey manufacturing is just one of our premier services we offer. It involves us handling all aspects of the manufacturing project, starting with design and prototyping to production, assembly, and lastly delivery. RBR Machine is truly a “one-stop-shop” for our customers, taking complete responsibility for the manufacturing project from start to end. Turnkey manufacturing reduces the headache on the customer and reduces overall time and resources. Focus on your core business operations, we’ll handle the rest.

Wire Cut EDM

RBR Machine is a leader in Electrical Discharge Machining. Wire EDM is a highly complex machining process that uses electrical discharges to precisely remove material in order to shape the workpeice. This is one of the most accurate machining techniques to produce custom parts. It works by passing a thin wire through the desired material. It uses electrical sparks to remove the unwanted material, thus creating the requested shape. Wire Cut EDM is the ideal process for industries such as medical, electronics, and aerospace.

CMM Inspection:

RBR offers CMM inspections even if you aren’t using us as your manufacturer. CMM Inpsection is a quality control procedure that leverages complex computer-aided measuring machines to review and measure the dimensions of a production run’s part. CMM Inspections are essential for a consistent product and for finding any potential production problems early on. This will reduce the risk of expensive production mistakes and lead time delays in the future.

CNC Milling Services

CNC Mills are robotic tools that use a rotating spindle to get rid of excess material. CNC mills come in a wide range of sizes and axis options. Milling services are primarily used for cutting harder objects like metals, but it will work on softer materials like plastics, aluminum, and brass. RBR Machine can handle any CNC Milling project you may have!

Our goal is the same with every client. We go above and beyond your expectations with our value added services, quality, and timely delivery. You can get quality milled production custom parts and prototypes fast with our unique milling strategies. You can sleep easy at night knowing RBR Machine is Our facility is AS9100D, ISO 9001:2015, ISO 13485, and ITAR registered.

Get Your CNC Machining Quote Now

CNC Turning Service

Our turning services use CNC lathes in order to cut symmetrical cylindrical or spherical pieces. The manufacturing technique in which you cut a workpeice on a CNC lathe is also referred to as turning. The process works by rotating the material on a vertical or horizontal axis, while the positioned cutting tool maneuvers down a linear path around the material.

You can get quality turned production parts and prototypes fast with our unique milling strategies. You can sleep easy at night knowing RBR Machine is Our facility is AS9100D, ISO 9001:2015, ISO 13485, and ITAR registered.

Start Your Accurate & Fast QuoteCNC Machining Materials

CNC Machining Nickle Alloys

- 718

- 625

- 925

- Monel

- corrosion resistant; aerospace, oil & gas

CNC Machining Stainless Steel Alloys

- 304

- 316

- 301

- 17-4

- 15-5

- 13-8

- corrosion resistant; aerospace, oil & gas

CNC Machining Carbon Steel Alloys

- 4130

- 4330

- 4340

- 1045

- 1018

- 8620

- high strength; aerospace, oil & gas

CNC Machining Titanium Alloys

- 6AL4V

- high strength, low weight

- aerospace, oil & gas

CNC Maching Aluminum Alloys

- 6061

- 7050

- 7075

- low mass, more cost effective

- aerospace, oil & gas

CNC Maching Magnesium Alloys

- extreme light-weight

- aerospace

- oil & gas

CNC Maching Composites

- extreme light-weight

- aerospace, oil & gas

We Service All Industries

Our goal is the same with every client. We go above and beyond your expectations with our value added services, quality, and timely delivery. Integrity and transparency throughout your whole project. RBR is a cut above the rest when it comes to the CNC machining services we offer our customers. Contact us today to see why!

View our IndustriesAdvantages & Challenges Of 5 Axis CNC Machining

Advantages of CNC Machining

Advantages of CNC Machining

The CNC machining process is one of the most accurate and repeatable machining processes ever created. The ability to leverage code and automation allow tolerances of +/-0.001″ to 0.005″ to be achieved. In some cases, CNC machines can work all day, making milling the perfect solution for a highly sought after part or production. Even when you use standard tooling, CNC machines are perfect for creating one-offs or larger production runs. Parts can easily be designed, tested, and implemented in no time! Quality custom parts are easily made using your choice of metal or plastic by cutting rather than transforming. There are endless industrial-grade materials that are compatible with CNC machining, such as milling and turning, as long as the part has adequate toughness for cutting.

Challenges of 5 Axis CNC Machining

1: First, complex parts come with higher costs. The simpler the shape, the more cost effective your project will be when you are milling or turning. As the number of axes increase and complexity of the part increase, so will the price in most cases.

2: Next, High production start-up costs. Accurate setup, loading, and tool programing is always required for every project. Costs can be lowered by using the same or similar setups for multiple parts. The less you reposition, the less you will be charged.

3: Slow Wire EDM. Wire EDM Machining is complex. It will only be able to cut electrically conductive materials. The machines

Trade-offs can often be mitigated by a few things:

- Material

- Design complexity

- Setup optimization

CNC Machining Applications

End Use Production:

CNC machining is an excellent choice for virtually any industry. End-use parts with performing-enhancing finishes, tight tolerances as small as +/- 0.001″, and authentic material choices.

Rapid Tooling:

Need a part or parts quick? CNC machining is perfect for creating complex fixtures or molds due to its availability to cut a large range of tough materials such as stainless steel.

Rapid Prototyping:

RBR Machine offers the cost-effective solution for prototype creation. Our skilled machinists, variety of metals, and plastics to choose from, and a quick turnaround time will equate to a successful project!

Why You Should Choose RBR Machine

Dedicated Customer Support and Quick Response Times:

5 axis CNC Machining comes with specific needs and we here at RBR Machine understand that. Having reliable and efficient support can make or break your project. That is why we take great pride in providing our clients second to none customer support. We are here when you need us! Our team members have decades of manufacturing and cnc machining experiences, which means we are able to answer any questions you may have and give you the support you need to keep your projects moving forward smoothly! Our support team’s response times are unmatched. You can be confident that we will be there for you when you need us most. We truly believe in offering exceptional customer service and will always go the extra mile to ensure you get the end result you desire!

Cost-Effective CNC Machining Services for Your Budget:

For any manufacturing project, cost is usually a major factor for many projects. That’s why RBR Machine is dedicated to providing our customers top-notch 5 axis CNC Machining services that are both effective and cost-efficient. As our technology progresses, so do our processes. Our main focus is giving you the best value for your investment. One-off prototyping or larger production runs, we have the knowledge and know how to help you achieve your goals within you budget. So why wait? Get in touch with us today to learn more about how we can help you get the most out of your CNC machining projects!

Unmatched CNC Capabilities for Complex Geometries and Tight Tolerances:

At RBR Machine, we have the machines and experience to handle even the most complicated geometries and tight tolerances with ease. Our 5 axis CNC machining capabilities are unmatched even under demanding circumstances. you can what were capable by clicking the link below. Our team of experts and engineers use the latest machines and techniques to produce your dream parts every time. Whether you need to create complex shapes, intricate details, or tight tolerances, we have the skills and experience to get the job done right. Why settle for anything less than the best? Get in touch with us today to learn more about how we can help you with your 5 axis CNC machining needs.

Innovative Machining Solutions for Improved Performance and Efficiency:

At RBR Machine, we’re always pushing the limits of what’s possible when it comes to 5 axis CNC machining. We believe in using the latest technology and innovative techniques to deliver better results and improved performance for our customers. Our team of experts are constantly exploring new ways to improve the efficiency and accuracy of our machining solutions, so you can get the most out of your projects. Whether you need to streamline your production processes, reduce costs, or simply improve the quality of your machined components, we have the solutions you need. With our innovative machining techniques, you can be confident that we’ll deliver the best possible results, every time. So why wait? Get in touch with us today to learn more about how we can help you improve your machining performance and efficiency!

RBR Machine Core Competencies

- 5-Axis mill/turn

- 5-Axis milling

- Large Capacity Milling: 165″ X 36″

- Zeiss CMM Inspections

- Wire EDM

- JSS Thread measuring

- Lathe: Turning up to 31’’ diameter & 30’ Length

- Swiss turning: Ideal for fittings and fasteners

- API Threading

- 3D CAD Model Design

What Is CNC Machining?

CNC is short for computer numerical control and is a popular manufacturing process that leverages automated, high-speed cutting tools to create complex parts from metal or other materials. There are many different types of CNC machines; 3-axis, 4-axis, and 5-axis milling machines, lathes, and routers are the most common. CNC parts are cut in many different way depending on what type of machine is used. For example, the material can be held in place while the machine moves or the toll can be stationary while the material is maneuvered and rotated, or both the machine and the workpeice can move together.

CNC specialists use computer programming and code to operate the tool paths of a CNC machine, this is based on the design of the final product. CAD models are primarily used as the design data. CNC machines, specifically 5-axis machines, can accurately and consistently handle a large range of materials. Some include plastics and metals, making them the go-to-choice for various industries including robotics, electronics , aerospace, medical, and medical. RBR Machine offers many CNC services and custom quotes using almost any material, some common materials include steel and brass, as well as stronger metals like titanium and plastics like Teflon & PEEK

Start Your Accurate & Fast Quote

Expert CNC Machining Services

RBR Machine has been providing custom part CNC Manufacturing services to customers for years. In fact, We are one of the leading 5 axis CNC machining services in nationwide. CNC machining is essential for most rapidly growing industries world wide. This state of the art technology allows for effortless automation, increased efficiencies, and larger cost savings for our customers. It's essential to produce custom parts that meet your exact specifications and tolerances every time. That is why RBR Machine is the obvious choice when you are picking your next CNC Machining service provider. Let us know how we can help you with your next successful project today!

Our 5-Axis CNC Machining ServicesCNC Machining FAQs

How Does the CNC Machining Process Work?

CNC machining is a complex manufacturing process the uses the process of removing material from a desired material to create a shape or part. Paths, holes, and other complex geometries are created by removing away material from the original material. CNC Machining is also referred to as ‘subtractive manufacturing’, which is the opposite of ‘additive manufacturing’. Additive manufacturing is done by adding material to build up a shape. Another common manufacturing process is ‘Injection Molding’. This is done by injecting a material into a mold until it is transformed into is final shape.

CNC machining is one of the most complex manufacturing techniques available. It is versatile and can be done to create parts in virtually any material. This alone makes it the go-to choice across a variety of industries.

How are traditional machining processes different than CNC machining?

Typically, more traditional machining requires an operator to operate the machine manually. This means the operator will manually control the tool to shape, cut, and/or form the desired part. In contrast, CNC machining is automated using different pieces of software and code. These computers are used to guide the machine. Automated cutting will always result in greater accuracy and repeatable results.

Traditional machining techniques are far more limited to the shapes and pieces they can created when compared to CNC machining. CNC machining is light years ahead when it comes to customization and versatility. CNC machines can create a vast range of pieces though its programming sequences. In today’s fast past world it would benefit most to use CNC machines as they are far more efficient than traditional machining.

Traditional machining will more often than not require highly specialized machinist to operate the machines, while CNC machining can be done by a less knowledgeably operator. This makes CNC machining available to many businesses and manufacturers.

What industries relying on CNC machining?

- Aerospace and defense

- Automotive

- Consumer electronics

- Power generation

- Consumer goods.

- Medical equipment and devices

- Robotics and automation

- Machine tool manufacturing

- Mold and die manufacturing

- Plastic and metal fabrication

When did CNC machining come about?

CNC machining was brought about an increased demand for many products during and after World War 2. John T. Parsons was one of the pioneers of the manufacturing process. We worked at the Wright-Patterson Air Force Base and used computational methods to create complex tapers in rotor blades for helicopters. MIT’s Servomechanisms Laboratory then developed a machine using computational methods and Cartesian coordinates for precise, automated fabrication. This marked the beginning of the evolution of CNC machining, which has continued to advance to this day.

What are the common quality and inspection methods for analyzing CNC produced parts?

Some of the common quality and inspection methods in the machining industry include:

-Dimensional inspection

-Visual inspection

-First Article Inspection (FAI)

-Coordinate Measuring Machine (CMM)

-Optical inspection

-X-Ray Inspection

-Radiography Inspection

-Hardness Testing

-Microscopic inspection

-Scanning electron microscopy (SEM)

-Destructive testing

-Non-Destructive testing (NDT)

RBR Machine has multiple CMM inspection options we provide our customers. Contact us today to learn more!

What are RBR Machines CNC Machining & Turning Capabilities?

RBR sets the standard for CNC capabilities in the industry. In general, here are our guidelines for machine size. If you have any questions, don’t hesitate to give us a call: (281) 469-6400

Our Core Capabilities: Click Here

Do you offer quick lead times for your CNC Services?

Yes! RBR Machine offers the quickest lead times on parts! We offer an expedite option as well. We know how important urgent deadlines are! Fill out our form or call us now! (281) 469-6400

Ready To Get Your CNC Machining Quote?

We provide quality machine parts for a variety of industries, including oil and gas, aerospace, automotive, solar and wind energy, nuclear and agriculture. With every client, our goal is the same: transparency and integrity, with a focus on exceeding your expectations for quality, delivery and value. Find out how RBR Machine can meet the needs of your company.

Get Your CNC Machining Quote Now